Ruby Nozzle og Colorfabb XT-CF20

kr.1.249,00 kr.749,00

- Passer til E2D v6

- Den eneste dyse du får brug for

- 750 g Colorfabb Carbon filament

Ikke på lager

THE OLSSON RUBY

SIX REASONS TO GET THE OLSSON RUBY

ONE NOZZLE

The Olsson Ruby will work with a huge range of materials.

PLA, ABS, CPE/PET, Nylon, and composites with abrasive additives such as Carbon fibre, Steel, Wood, Boron Carbide, Tungsten and Phosphorescent pigment, are some of the materials sucessfully tested so far.

HIGHLY WEAR RESISTANT

The ruby mounted at the tip makes sure that even the toughest materials will be printable. It was originally designed for printing with Boron Carbide (B4C), the third hardest known material in the world.

EXCELLENT HEAT CONDUCTIVITY

Since most of the Olsson Ruby is made from brass, with its excellent heat conductivity, performance and throughput is first-class.

VERIFIED PERFORMANCE

People all over the world have been testing different iterations of the ruby nozzle since early 2016. We are very happy to have received only good printing results from this community.

SPEED

By using the 0.6, 0.8mm and High Output versions it is possible to reach a higher throughput and speed than ever before for abrasive materials, while retaining wear-resistance and reliability.

MANUFACTURING QUALITY

The Olsson Ruby is manufactured, assembled and tested in a high-quality facility in Sweden.

ColorFabb XT-CF20 is a copolyester based carbon fiber composite material that is based on the unique Amphora 3D polymer from Eastman Chemical and is loaded with no less than 20% specially sourced carbon fibers suitable for 3D Printing.

Combining carbon fibers in filaments material is not a new idea, but colorFabb has been able to combine a lot of desired properties into 1 new material :

- Extreme High Flex Modulus (6.2 GPa), twice as stiff as PLA/PHA

- Moderate strain at break (8-10%), so no extreme brittle filament, but toughness

- High Glass Temp. (Tg = 80C)

- Very high Melt strength

- Very high Melt Viscosity

- Good dimensional accuracy and stability

- Low odor / Styrene Free solution

- Easy processing on many platforms

- High attractive matt black surface

CARBON FIBER IS ABRASIVE

A special point of attention is the abrasive nature of the carbon fibers. In general these fibers will accelerate the nozzle-wear of brass nozzles, much faster than unfilled filaments. There colorFabb recommends to use nozzle’s from Stainless steel or hardened copper alloys.

APPLICATIONS :

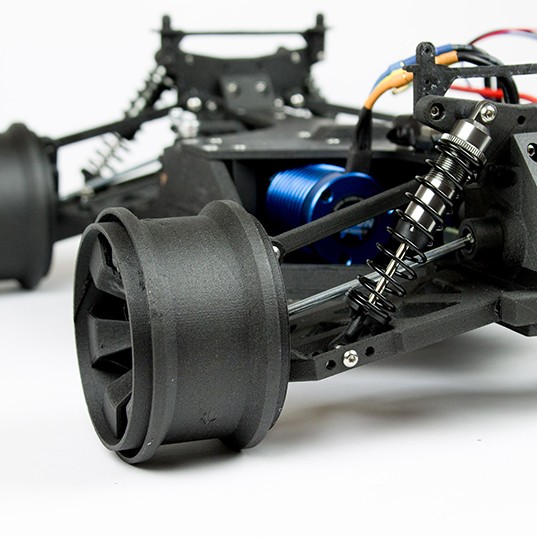

Just think of all the great applications for a variety industries, that now will have a material that performs according to expectations. Functionality, stiffness, dimensional stability, heat resistant, what more can you ask? Applications in the RC Industry / Drones / Aerospace / Automotive / Prototyping and many more can now be developed on your desktop 3D Printer.

AMPHORA 3D POLYMER

ColorFabb XT-CF20 is produced wih AMPHORA 3D Polymer from Eastman Chemical.

Amphora 3D Polymers is a specially developed co-polyester just for 3D Printing. It’s toughness and high meltstrength makes it the perfect material for producing fiber reinforced composites, providing the necessary viscosity for 3D printing, combined with a high toughness in the filament and end application

| Vægt | 1 kg |

|---|---|

| Størrelse | 23 × 23 × 12 cm |

Kun kunder, der er logget ind og har købt denne vare, kan skrive en anmeldelse.

Anmeldelser

Der er endnu ikke nogle anmeldelser.